Page 6 of 11

Re: RT rebuild thread

Posted: Sat Jan 28, 2012 2:32 pm

by stylussprinter

hearbear wrote:DH2 wrote:pigeondave wrote:Don't know if you have a different supplier.

Nope, that's the supplier I had in mind. Any issues at all? I emailed Ricky about the wiring, to check it is a single element, whilst I am drawing a wiring diagram for my new loom.

Dave

Thats the screen I got it has twin elements one on each half of the screen but he recommends joining the two half's together in series.

I will collect the carpets myself as coming to work in London for the week and that will pass an evening.

Cheers George

Very wise to come down now George

You may be needing a passport soon

Re: RT rebuild thread

Posted: Sat Jan 28, 2012 3:09 pm

by hearbear

late 2014 before then and most think it is a daft idea

Re: RT rebuild thread

Posted: Sat Jan 28, 2012 5:19 pm

by stylussprinter

Only having fun at your expense George

Re: RT rebuild thread

Posted: Mon Jan 30, 2012 2:34 pm

by DH2

Spent all day on Saturday getting the body detached from the chassis - wasn't as bad as I thought it was going to be, once I had a technique working, just a bit time consuming. Have to remove the doors as the hinges are attached to both chassis and body.

I was then able to hoik it up and get it sitting on top of the chassis. Unfortunately, my arms aren't long enough to be able to get the whole thing lifted and out of the garage, and my helper was not around to assist.

Before getting the body out of the way for a while, I remembered that I wanted to do a mock-up of a roll cage. So I spent a while getting all Blue Peter on the car, and played around with some ideas for a cage design.

DH2

Re: RT rebuild thread

Posted: Mon Jan 30, 2012 4:39 pm

by stylussprinter

Very well done that man

Now we all know it can be done Dave --- you never know when WE may need to do it

Re: RT rebuild thread

Posted: Mon Jan 30, 2012 5:36 pm

by DH2

stylussprinter wrote:Very well done that man

Now we all know it can be done Dave --- you never know when WE may need to do it

Thanks. It wasn't as bad as I was expecting, but could be a bit trickier on a classic bodyshell, and even more so one with the front end still on it.

The door hinge design on mine is a bit nasty, so have been looking at the build manual ones, or maybe a combination with those done by spegru

here, as the door attachment there is neater.

Next up - time to start cutting the chassis up to make the gearbox fit. Never done it before, let's hope it all stays square, wish me luck!

Actually there must be some people here with a Type9 in the chassis... how comes mine doesn't fit? I do have it as far back in the chassis as I can - front edge of the gearcase is just behind the end of the passenger footwell.

Dave

Re: RT rebuild thread

Posted: Mon Jan 30, 2012 5:57 pm

by stylussprinter

Virtually everyone will have a Type 9 . When the FORD bellhousing bolts onto the gearbox , it's that which decides how far back it will go into the tunnel . My box just protrudes infront of the 25mm tube tunnel surround by about 10/12mm's , so the bellhousing sits about 20mm's infront of the bulkhead .

The engine doesn't sit in the centre of the engine bay ' by design ' . The tunnel dictates that angle which was done by JP to help balance the corner weights plus give the driver more footwell space . Maybe the Vauxall engine mounts were made to sit it slightly more forward than SSC's standard fitting

To my knowledge , no one has had to widen the tunnel in order to fit the type 9 box

Fury's are tighter around that area though--- hence JP's redesign when thinking of the Stylus which camw after the Fury

Re: RT rebuild thread

Posted: Mon Jan 30, 2012 6:36 pm

by DH2

stylussprinter wrote:Virtually everyone will have a Type 9 . When the FORD bellhousing bolts onto the gearbox , it's that which decides how far back it will go into the tunnel . My box just protrudes infront of the 25mm tube tunnel surround by about 10/12mm's , so the bellhousing sits about 20mm's infront of the bulkhead .

The engine doesn't sit in the centre of the engine bay ' by design ' . The tunnel dictates that angle which was done by JP to help balance the corner weights plus give the driver more footwell space . Maybe the Vauxall engine mounts were made to sit it slightly more forward than SSC's standard fitting

To my knowledge , no one has had to widen the tunnel in order to fit the type 9 box

Fury's are tighter around that area though--- hence JP's redesign when thinking of the Stylus which camw after the Fury

Hmmm... you can see on the previous page where the gearbox is sitting in the tunnel. I can't use the "standard" Ford bellhousing as it is the wrong bolt pattern for the engine, so maybe my bellhousing is slimmer, as it is not the limiting factor as to how far back it can go (until it trys to go down the tunnel of course). The car has always run a Manta gearbox to date, and I had assumed the tunnel was sized around that.

When you say the engine doesn't sit in the centre, presumably you mean offset to the passenger side... but still fairly straight in the chassis? Where I had sitting in fitted a couple weeks ago, it was well squint, but that was caused by the box not fitting in the tunnel very well, due to that angled front chassis member on the left of the drivers footwell.

Re: RT rebuild thread

Posted: Mon Jan 30, 2012 6:59 pm

by MattD

Re: RT rebuild thread

Posted: Mon Jan 30, 2012 7:28 pm

by stylussprinter

No Dave , definitely not straight in the chassis , offset to passenger AND at an angle which is what you call squint

My engine is MUCH closer to the kerbside suspension rocker/shock top mount --- that's normal . The complete install follows the tunnel angle.

I just sent you photos on text Dave

Re: RT rebuild thread

Posted: Mon Jan 30, 2012 7:47 pm

by DH2

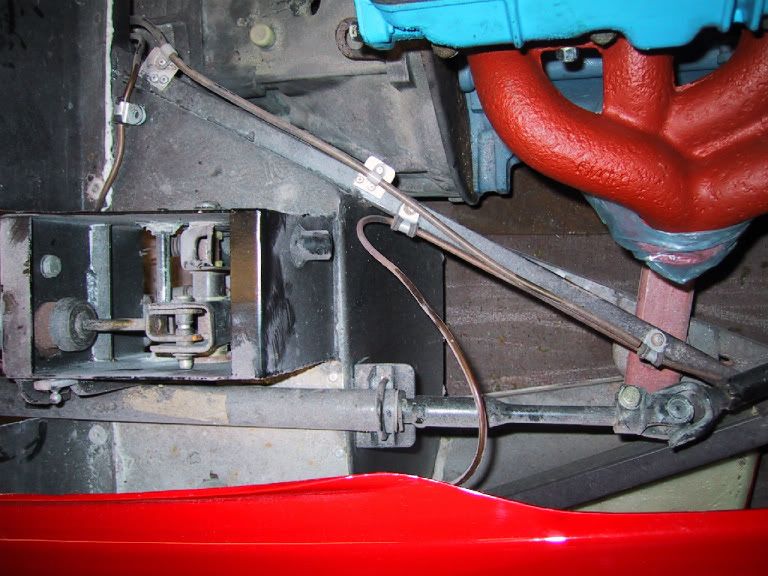

A couple of photos which sort of show how "squint" it is...

Re: RT rebuild thread

Posted: Mon Jan 30, 2012 7:57 pm

by stylussprinter

Yep , that's about right . You'll have to set your gearbox so that it just misses the left and right tunnel sides --- which will be around 3 to 5 mm's . Just to make it easy I hammered carefully each top steel gearbox lid edge a little which are the widest as the tunnel narrows at the top . These enginesrun so smoothly these days , there's no problem at 3mm's even .

Re: RT rebuild thread

Posted: Mon Jan 30, 2012 8:43 pm

by DH2

Hmmm. It causes more conflict for my inlet against the bonnet if I leave it as-is though. I'll get some string down the tunnel and see what I can see.

Re: RT rebuild thread

Posted: Mon Jan 30, 2012 11:16 pm

by stylussprinter

DH2 wrote:Hmmm. It causes more conflict for my inlet against the bonnet if I leave it as-is though. I'll get some string down the tunnel and see what I can see.

Why's that then --- it doesn't look any bigger than most other engines people have tried

Once you've fitted a decent sump from either Dunnell(the cheapest)or Raceline and the bottom dips just 35/40mm's below the chassis rails , the engine etc should clear easily ----- unless of course you intend an Eaton S Charger on top

Re: RT rebuild thread

Posted: Mon Feb 06, 2012 2:25 pm

by DH2

Unfortunately, the weather prevented much progress over the weekend.

My suspension man came round on Saturday morning to do some chassis measuring, so we lifted off the main body tub to be left with just the chassis.

The body has become a garden ornament for a while...

... which promptly turned white before I've had chance to secure/support it better and tarp it over.

Dave